[ad_1]

Sponsored by Eaton.

Electrical autos are remodeling the transportation trade, providing a cleaner, extra environment friendly, and extra sustainable method to transfer folks and items. Nevertheless, not all EVs are created equal, and completely different purposes require completely different powertrain options. For industrial autos, resembling buses and HD vehicles, efficiency, reliability, and value are important elements that decide the success of electrification. That’s why Eaton, a world chief in energy administration applied sciences, has developed a variety of modern EV transmissions which are designed to satisfy the particular wants of electrical industrial autos. Eaton’s new HD 4-speed EV transmission is a purpose-built answer that delivers superior efficiency, effectivity, and integration flexibility for heavy-duty purposes.

A standard false impression is that EVs don’t want transmissions, since electrical motors can present on the spot torque and function over a large pace vary. Nevertheless, this isn’t the case for a lot of electrical industrial autos, which should cope with heavy hundreds, steep hills, and freeway speeds. A single-speed or direct-drive system both requires a really giant and costly motor to offer sufficient energy and torque to the wheels or limits the efficiency and vary of the automobile with a fairly sized motor. A multi-speed transmission, alternatively, can broaden the working vary of the motor, scale back its dimension and value, and enhance the effectivity and efficiency of the automobile. A multi-speed transmission additionally allows improved regenerative braking efficiency, recovering extra vitality from the automobile’s movement and decreasing put on and tear on the inspiration brakes.

Whereas transmissions are useful for EVs, they don’t want as many gear ratios as typical autos with inside combustion engines (ICEs). It is because electrical motors have a a lot quicker and smoother torque response than ICEs and may present steady peak torque over a a lot wider pace vary. Because of this fewer gears are required to cowl the identical working vary, and that the automobile can spend extra time within the optimum gear for effectivity and efficiency. For instance, a typical diesel truck may want a 10-speed transmission to deal with completely different street circumstances, whereas an electrical truck can obtain the identical efficiency with a 4-speed transmission. Eaton has leveraged its experience in gear design and shifting know-how to develop EV transmissions that provide the optimum variety of gears for various purposes, starting from 2-speed to 6-speed.

There are three primary forms of EV powertrain architectures that can be utilized for industrial autos: central drive, e-axle, and direct drive. Every of those architectures has its personal execs and cons, relying on the appliance, efficiency necessities, packaging constraints and value elements. Eaton’s EV transmissions are presently targeted on central drive architectures, which include a chassis-mounted motor and transmission linked to the axle by a driveshaft. This structure provides a number of benefits, resembling low complexity, confirmed reliability, ease of integration, flexibility of motor choice, and glorious battery packaging house. Eaton’s EV transmissions may also be tailored to the e-axle structure, which integrates the motor and gearbox into the inflexible axle, providing one of the best battery packaging house availability. The direct drive structure, which eliminates the transmission and connects the motor on to the wheels, isn’t advisable for heavy-duty purposes, because it requires a big and costly motor and limits the efficiency and vary of the automobile.

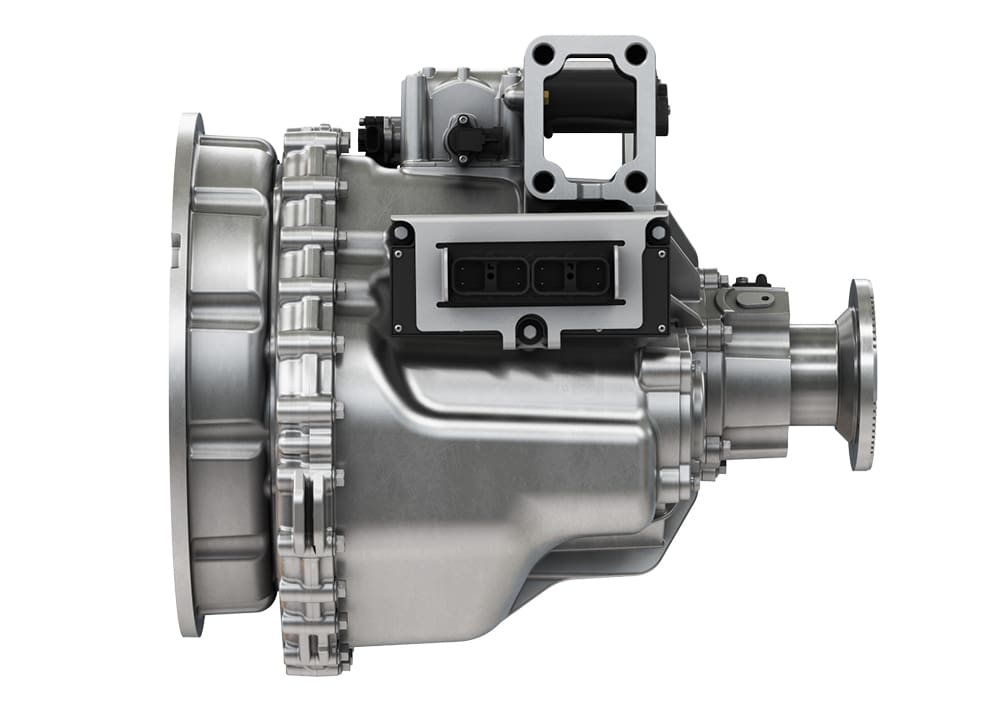

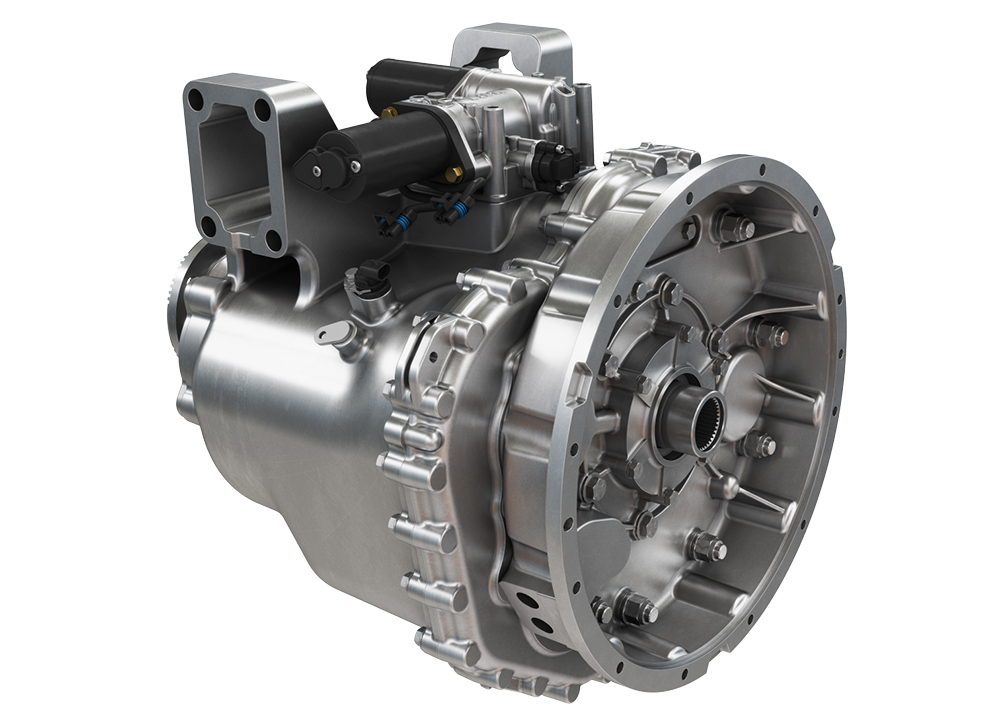

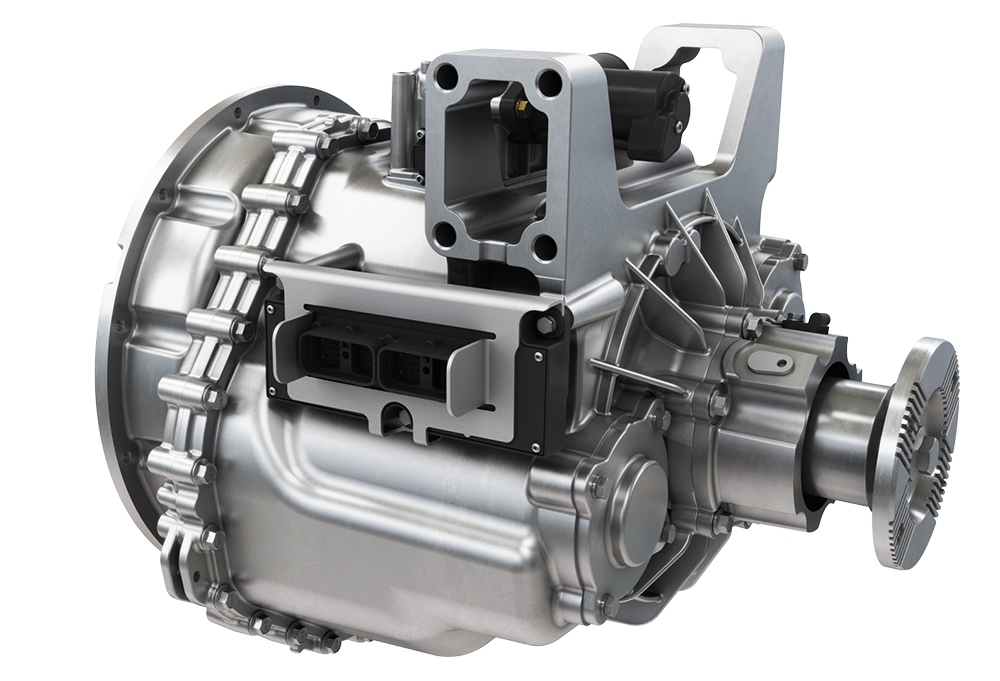

Eaton’s HD 4-speed EV transmission is a state-of-the-art product that’s designed for heavy-duty purposes, resembling beverage, vacationer bus, yard tractor, drayage, metropolis dump truck, municipal and logistics vehicles. It has a most torque capability of 2600 Nm and a most enter pace of 5000 rpm, making it appropriate for autos with a gross mixture weight of as much as 43 tons. It additionally options an all-aluminum enclosure, helical gearing, a transmission-mounted management module and an built-in electrical actuation system, leading to a light-weight, high-efficiency and low-noise transmission. Eaton’s proprietary shift management logic ensures clean and seamless gear modifications, whereas the rear PTO possibility allows auxiliary energy for equipment. The HD 4-speed EV transmission additionally provides straightforward integration with a number of motor choices, because of the SAE #2 motor adapter. The HD 4-speed EV transmission is presently within the B-sample stage, with the beginning of manufacturing deliberate inside 2024.

[ad_2]