[ad_1]

Q&A with Smartville CEO and co-founder Antoni Tong

What do EV batteries have in frequent with athletes and politicians? As soon as they age out (or get voted out) of their positions, they’ve the chance to have a profitable (and within the case of batteries, helpful) second profession. Repurposing depleted EV batteries for stationary storage functions will likely be a crucial a part of the longer term EV ecosystem.

Nonetheless, there are complicating components: battery packs are available many alternative sizes and type components, and particular person packs could retire from the street at completely different factors of their lives, so their remaining capability and total well being can fluctuate enormously. Tips on how to assemble this motley mélange of used battery packs right into a smoothly-functioning stationary storage system?

Smartville, which just lately gained a $5.9-million grant from the DOE, has developed an answer. The corporate’s new Smartville 360 ESS is a scalable second-life vitality storage system that’s designed to include battery packs from completely different producers (at the moment, Tesla and Nissan), at various ranges of well being, into one unified system. Smartville at the moment has a pilot undertaking up and operating on the College of California San Diego.

The corporate claims Smartville 360 provides the bottom embedded emissions and one of the best worth per kilowatt-hour of any storage resolution in the marketplace. Smartville additionally hopes to distinguish itself from rivals by tailoring options to the wants of various kinds of clients.

CEO and co-founder Antoni Tong just lately defined to Charged how the system works, and the way the corporate procures batteries and prepares them for profitable second careers.

Charged: Let’s begin at the first step. Inform me extra about the place you supply the used batteries from.

Antoni Tong: We work with a wide range of battery procurement companions throughout the worth chain. For some battery procurement, we work with OEMs or battery service firms which can be immediately working with OEMs. For instance, Nissan. They’ve manufacturing house in Tennessee, and so they have repurposing applications by way of their North American headquarters, so we will supply, procure and quality-control batteries immediately from them.

We additionally work with Tesla Mannequin 3 and Y packs, as they’re US market leaders in EV gross sales. When it comes to quantity of battery capability that’s on the market, 60% to 70% are Tesla Mannequin 3 and Y packs. These we procure by way of auctions, insurance coverage write-offs and third-party dismantlers.

Charged: If a automotive will get totaled, you would possibly purchase the battery pack on the salvage market?

Antoni Tong: Right. The volumes really are larger than we thought. We’ve got seen at two of the main insurance coverage public sale websites, about 1% of the automobiles are coming by way of that pipeline in yr one, and you will note about 15% of them earlier than yr 10. These are pretty new and qualifiable batteries for reuse. Our market examine signifies that over one GWh price of batteries will likely be accessible for repurposing within the subsequent three years.

Charged: Your Smartvlle 360 platform is designed to make use of batteries from completely different automobiles—any battery chemistry, any kind of battery, appropriate?

Antoni Tong: Sure, that is precisely the design-for-application strategy we took to optimize the combination value and competitiveness of our merchandise, and scale back the chance of procurement. We’re pretty assured that the merchandise are agnostic with regard to OEMs and chemistries.

There’s just one nuance—sometimes, we design batteries by the category of voltage. Presently, greater than 90% of automobiles are within the 400-volt class. We do begin to see new vehicles and buses utilizing 800- or 1,200-class voltage, and that requires some retooling and replace of energy electronics on our finish.

There are completely different colleges of repurposing—the teardown mannequin or the whole-pack repurposing mannequin. Smartville does a whole-pack repurposing mannequin.

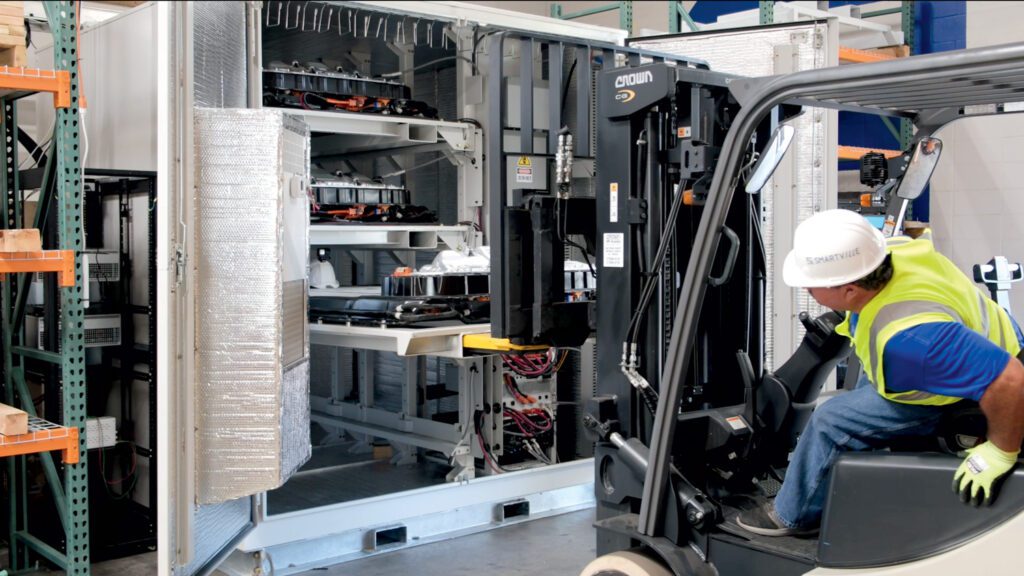

Charged: What do you bodily must do with a pack to put in it into your machine? Certainly you don’t simply take the entire battery pack and stick it within the cupboard?

Antoni Tong: That’s precisely what we do. Let me provide you with some causes. There are completely different colleges of repurposing—the teardown mannequin or the whole-pack repurposing mannequin. Smartville does a whole-pack repurposing mannequin.

There are enterprise fashions in Asia and Europe doing teardown, however there are two causes that that is going to be exceedingly difficult. One is the economics. On this market house, to do that requires excessive labor prices for reintegration. You’re additionally tampering with a wonderfully sealed and engineered pack to rebuild a system that introduces new elements and controls, which can combine in a producing defect.

The second motive is the pattern of how battery packs are being engineered. You might be seeing larger form-factor modules, one thing like cell-to-pack design, which make the pack nearly indestructible, so the pathway for the teardown mannequin nearly doesn’t exist. For instance, Tesla Fashions 3 and Y, and different large-format battery packs that we’re beginning to see out there.

For these causes, we’re attempting to repurpose immediately on the pack stage. Nonetheless, I ought to have prefaced, it’s in a roundabout way sticking the pack into the Smartville 360. We do qualification, we do cooling line integrations, we do high quality checks, not solely on the batteries but in addition on the crucial elements throughout the pack. That features the BMS, communications, cooling strains, seals, isolation detections, contact qualities. So, all that we’re going to be reusing outdoors of the battery will likely be certified earlier than we combine them.

Charged: Inform me extra in regards to the qualification that you simply do on these battery packs.

Antoni Tong: Qualification is extraordinarily necessary for our enterprise mannequin, and we hope to construct a differentiating strategy in that house.

Qualification is extraordinarily necessary for our enterprise mannequin, and we hope to construct a differentiating strategy in that house.

What we do typically begins even earlier than we contact the batteries. We work with service suppliers, dismantlers, a few of them even earlier than the batteries come off the automobiles. We offer them with {hardware} and protocols so they can do preliminary sniffing of the batteries—taking footage, studying manufacturing marks, studying VINs. We even have a tool that may learn CAN buses on the BMS to get odometer readings, mileage, accumulative cycles, so we will draw a map of the tough class of health of these batteries.

As soon as we decide a few of the batteries are good, and get them to our manufacturing facility, then we’ll conduct the testing we name “application-appropriate.” As a result of once they had been within the automobiles, all of the calibration, all of the readings, all of the BMS had been reporting how the batteries operated within the automobile. We take a look at them on their high quality for vitality storage functions. We recalibrate their state of well being and their state of cost, after which we prep them for integration. That process builds up a powerful physique of knowledge intelligence that we’re in a position to make use of to foretell and assure efficiency.

Charged: Inside the Smartville 360, you’ve bought to attach the communication strains to the BMS, you’ve bought to attach the coolant strains, and all these connections should be completely different for each completely different pack, proper?

Antoni Tong: This is among the distinctive toolings we needed to do. The shape issue matches the vast majority of the EV packs. And inside every Smartville 360, we use the identical kind of battery—not solely the identical fashions but in addition very shut mannequin years. Each time we turn out to be suitable with a brand new kind of battery pack, the very first thing we do is retool the cables and retool the communication connections. However we discover this to be largely comparable, and we’ve a cable guide and suppliers which can be conversant in a number of these retoolings within the automotive house.

Charged: So that you don’t combine and match packs inside a single Smartville 360 unit, however every completely different unit could possibly be utilizing various kinds of packs.

Antoni Tong: Right.

Charged: You describe the Smartville 360 as a plug-and-play machine. How does a buyer join it into their electrical service for peak shaving, backup energy or different functions?

Antoni Tong: Our system could be configured for each DC and AC couplings. For the AC coupling, it comes with the inverter pre-integrated and absolutely turn-key. Our EMS system, regardless of {our capability} to work with batteries with differing types and well being, will coordinate the lower-level management so the client will solely see one unit of batteries to dispatch. A undertaking developer will then take our EMS management interface and incorporate it with a bigger site-level controller, which incorporates different vitality elements akin to renewables, masses, grid-metering and switches.

The EMS is what they use to dispatch our ESS. For storage, it is dependent upon functions. There are numerous, many alternative controls you are able to do. You talked about just a few: peak shaving, that’s trying on the time-of-use worth; demand discount. It’s extra sophisticated what’s the penalizing tier of the native utility. So, all these are completely different case-by-case conditions.

Charged: There should be a software program product that goes together with it. Is that one thing that you simply present or can it work with completely different techniques?

Antoni Tong: Each. Our techniques include the EMS that enables the integrator to dispatch the batteries. We additionally could be suitable with different extra highly effective EMS techniques that the client would possibly use.

Charged: I suppose second-life battery know-how has come a great distance within the 10 years because you started within the trade. What are a few of the enhancements and improvements which have occurred?

Antoni Tong: Previously 10 years there have been a number of pilots and trials, typically OEM-initiated, sometimes working with builders or integrators to do demonstration initiatives.

Over the past couple of years, we’ve seen progress within the quantity of batteries, the procurement mannequin being additional diversified, and a number of firms engaged on completely different batteries. We’re beginning to see the emergence of options actually focusing on a aggressive enterprise mannequin within the stationary cupboard space. Relying in the marketplace sector they’re specializing in, the worth construction is likely to be completely different. However that is nonetheless in a really early stage.

Charged: What are a few of the potential clients, and the way do their wants differ?

Antoni Tong: Totally different firms are specializing in completely different buyer sectors. Smartville immediately is specializing in about 100 kilowatt-hours to multi-megawatt-hours of set up as a market entry. We’re focusing on techniques for business and industrial clients, or a leg as much as a small grid-integrated stage, however not like a gigawatt stage of storage but, as these functions require a lot bigger manufacturing scales and financing automobiles than we’re able to immediately.

Charged: Smartville was based in 2019. What stage in your growth are you at? Are you continue to engaged on pilots or do you will have some precise buyer installations up and operating?

Antoni Tong: To this point, we’re on the scaling level. Our first pilot-level product is Smartville 360, and proper now, we’re at iteration two. With iteration one, we had one set up accomplished final yr as a pilot. It’s backed by California Vitality Fee funding.

We’ve got 4 concurrent pilots ongoing proper now. Smartville 360 model two is geared in the direction of certification below the UL 9540 framework and is focusing on low-rate manufacturing. With that product, we’re doing our first business supply to a utility firm. We hope to showcase our merchandise and underlying options in September on the RE+ Conference. We even have a few utility, business and auto OEM clients within the pipeline.

Charged: What do the auto OEMs use stationary storage for?

Antoni Tong: A few of them desire a proof of idea on their batteries. They’ve incentives to see value variations, ought to coverage come that makes them liable for battery packs which can be of their automobiles or creating an inner software ecosystem for his or her battery packs.

Charged: The OEMs assume there is likely to be regulation sooner or later that may require them to assist second-life batteries?

Antoni Tong:Typically, OEMs don’t wish to comply until there’s a sturdy monetary incentive. What I see isn’t solely the chance of future insurance policies, but in addition different monetary incentives. As a result of these days, battery pack chemistries are shifting towards low-cost, low-supply-risk uncooked supplies, akin to shifting from NCM to iron phosphate. The OEMs would possibly see little to unfavorable worth in recycling solely, which means that they’ve extra prices on their palms for end-of-life batteries. So hopefully, it’s a mixture of coverage push and the monetary incentive to drive to a reuse and recycle mannequin.

These days, battery pack chemistries are shifting towards low-cost, low-supply-risk uncooked supplies, akin to shifting from NCM to iron phosphate. The OEMs would possibly see little to unfavorable worth in recycling solely.

Charged: So recycling is in some circumstances not economically viable? How does that relate to second-life functions?

Antoni Tong: We see challenges on the revenue facet on the battery supplies. Possibly two years in the past in the course of the top of COVID, battery uncooked supplies may fetch excessive costs, however the worth has been down by greater than 50% since COVID subsided.

We additionally see completely different revenue alternatives for various chemistries. The sooner batteries with excessive nickel, manganese and cobalt content material fetch a greater worth, however batteries should not made this manner these days. Very low nickel and cobalt contents immediately. The iron phosphate cells, they’re principally iron and rust and a few lithium. These really carry a price to the top proprietor. It’s not an issue for OEMs immediately as a result of they aren’t liable for these packs. However as soon as they do turn out to be responsible for these prices, that’s a terrific monetary incentive to discover a accountable but cost-effective end-of-life resolution. And I hope at the moment, reuse turns into an answer earlier than recycling.

Once we discuss to collaborators and potential clients, we all the time say our enterprise mannequin isn’t in competitors with recycling. We’re in a complementary place with recycling, as a result of we and the recycling entities are utilizing very comparable processes of logistics, delivery and procurement. The batteries have to come back out of the automobiles, must be sorted, must be transported. But when we will decide the batteries which can be usable for us, the associated fee to the recycler for procuring the rejected batteries will likely be decrease. On the similar time, once we triage massive portions of batteries for repurposing, we make it simpler for these end-of-life batteries finally to get to the door of the recycling plant.

Charged: Inform me about the way forward for sourcing packs. When do you assume you’re going to see a number of precise end-of-life battery packs coming in the marketplace?

Antoni Tong: This can be a superb query. Our retaining charge, which suggests the salvage charge on the automobile facet, can be pushed by the numerous progress of the EV house. We see north of gigawatt-hours of used batteries accessible as early as 2027. That’s a major quantity, a lot bigger than our goal procurement mannequin inside Smartville’s enterprise goal.

We see north of gigawatt-hours of used batteries accessible as early as 2027…a lot bigger than our goal procurement mannequin inside Smartville’s enterprise goal.

However there’s a nuance as as to whether they’re actually end-of-life. There isn’t any clear line {that a} battery used past 80% remaining capability is true end-of-life. There will likely be a spectrum, and we proceed to work with batteries of all ages. Some got here proper off the manufacturing facility flooring and bought into accidents. Some persons are driving previous Nissans all the way down to solely 40 miles of vary, and we’ve these batteries at our manufacturing facility as nicely. The important thing right here is to determine good battery information analytics to offer the prescribed service life and efficiency in our built-in product.

Charged: My LEAF is all the way down to 80 miles of vary, nevertheless it will get me the place I have to go, so that you gained’t get that battery pack for a very long time.

Antoni Tong: Proper. However so as to add to that, a number of our motivation can be coming from sustainability aims. Simply to throw a quantity on the market, a brand new EV must drive about 13,500 miles to equal the embedded carbon emissions in comparison with a gasoline automotive, in keeping with Reuters. Which implies you probably have a automobile that will get totaled earlier than yr three, yr 5, that’s a extra polluting automotive than gasoline. [Editor’s note: There are widely varying estimates as to the mileage required to cancel out an EV’s “carbon backpack.”]

You might have tons of battery belongings on the market which can be being floor down for materials. Alternatively, if we will decide them up and produce them a second life, we will fulfill their carbon emission discount objectives.

Charged: In California they’re introducing some incentives for stationary storage, and I feel the IRA and the BIL deal with this too. Are there state and federal incentives that you simply’re in a position to faucet into?

Antoni Tong: There are sturdy incentives for stationary storage within the IRA, however there are wrinkles for the road of enterprise we do. For instance, because the IRC part 48 Vitality Funding Credit score stands immediately, second-life batteries had been omitted of the know-how candidates to obtain project-wide tax incentives. Nonetheless, we’ve a really sturdy case that this can be a shifting of software—it’s a battery that’s not purposely for stationary storage and we, by way of engineering, developed a brand new line of product. I feel we will make a case for the product to be certified—however there’s threat there.

And if you’re certified for a sure share of home manufacturing, you qualify for extra tax rebates. Which, curiously for Smartville, our merchandise have very, very excessive percentages of home content material. Because of our low-risk provide chain and localized manufacturing apply, our enclosures, our energy electronics, interface phases, and the batteries, are sourced or manufactured within the US, versus different vitality storage merchandise that you simply sometimes see—batteries are largely coming from abroad.

This is among the issues that the battery circularity trade as a neighborhood is investigating. One chance is that we submit initiatives for a personal letter ruling (PLR) on qualifying below the IRA. We additionally look to see campaigning and lobbying efforts that might qualify these merchandise for tax incentives. In any case, reaching scalable repurposing, in our opinion, is a key step to reaching a sustainable home lithium-ion battery provide chain.

This text appeared in Concern 65: July-September 2023 – Subscribe now.

[ad_2]