[ad_1]

Sponsored by Pickering Interfaces.

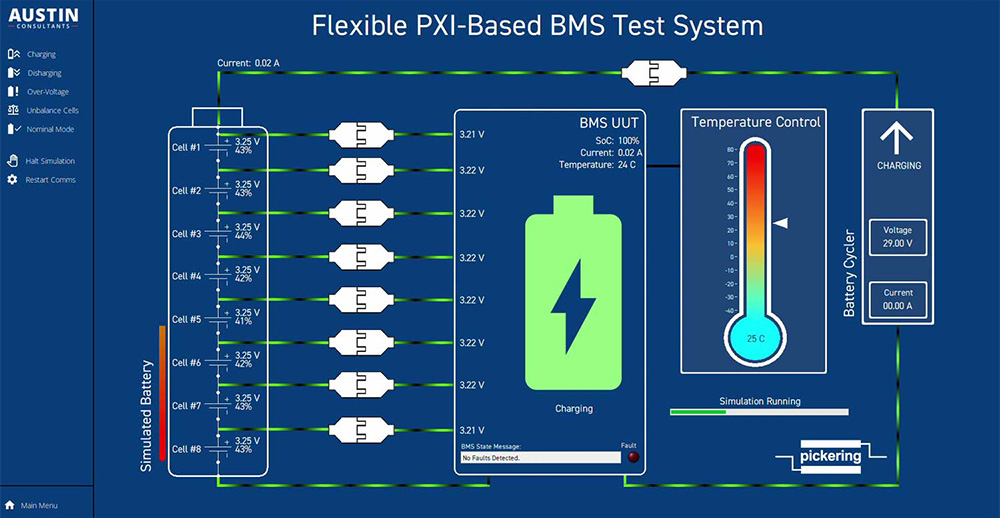

Herein, we talk about the targets of BMS verification and clarify how simulation with hardware-in-the-loop offers a wealth of knowledge, saves time and is safer than working with precise dwell cells. We additionally clarify how a BMS HIL check system might be created utilizing PXI simulation modules from Pickering Interfaces.

Battery Administration Methods (BMS)

Electrical automobile (EV) battery packs – which might include from just a few dozen to greater than 1,000 cells – have to be managed for optimum efficiency by way of releasing and accepting energy. The packs should even be monitored to report SoC and SoH (state-of-charge and -health, respectively) to the techniques using them. Additionally, security measures/options have to be current to isolate the packs (or modules/banks of cells) in case of a fault. These roles are all carried out by the BMS.

Security

Security is an important consideration wherever battery packs are used. In automotive purposes, the packs and all automobile/platform parts that electrically connect with them (together with the BMS) are thought of hazardous gadgets and should adjust to ISO 26262.

BMS Design & Verification

Most corporations undertake a TDD (test-driven growth) technique when designing a BMS. This allows them to not solely optimize the battery pack’s measurement (each bodily and vitality capability), but in addition confirm the performance of the BMS all through the product growth lifecycle.

Typical top-level practical necessities for a BMS embrace:

- Voltages have to be monitored on the battery pack’s inputs and outputs, and on the particular person cell degree.

- Present circulate into and from the pack have to be monitored.

- SoC and SoH needs to be monitored and made out there to techniques that draw energy from the pack and which cost it.

- Thermal administration – for instance, lithium-ion cells carry out finest between 10 and 45oC, so the BMS should management the heating or cooling of the pack accordingly.

- The BMS should shield towards in-use circumstances, resembling over-charging and fault circumstances (like a person cell failing or wires breaking). It should additionally shield towards human errors, resembling getting the polarity incorrect throughout a upkeep or restore process.

Verifying via check that the above necessities and others have been met is greater than only a growth process, nonetheless. Each manufacturing unit have to be functionally verified as a part of its high quality assurance.

Simulation with {Hardware}-in-the-Loop

BMS growth with HIL (hardware-in-the-loop) is important. Nevertheless, using an precise battery pack presents challenges, together with:

- Performing over-voltage checks is harmful – with the danger of fireside or explosion.

- It’s not straightforward to vary the voltages of particular person cells, that means it’s troublesome to confirm that the BMS’s cell balancing perform works.

- The place the monitoring of particular person cell voltages is worried, it’s solely doable to verify what the BMS thinks it’s seeing. However what are the true cell voltages?

- How can the BMS’s temperature monitoring perform be checked with out subjecting the pack to harmful temperature extremes?

There may be additionally the difficulty of check repeatability and documenting check circumstances and outcomes. Take a look at set-up and the reporting of outcomes are each open to human error. This implies the accuracy (and by extension, validity) of the BMS verification knowledge may very well be referred to as into query.

The answer to those points is simulation. It removes the necessity to work with dwell cells, making it safer. The voltages provided to the BMS in lieu of particular person cells might be monitored, so there are values towards which the BMS’s observations might be in contrast.

Simulation can also be extremely repeatable, as fault circumstances, resembling damaged wires and overheating cells, are far simpler to simulate than they’re to copy with dwell cells. The recording of check circumstances (stimuli utilized) and outcomes are simple.

Excessive Voltage Switching

Pickering Interfaces’ PXI excessive voltage switching modules assist sizzling switching of 0.25A at as much as 7.5kV (DC and AC peak) and chilly switching as much as 9kV (DC and AC peak). Additionally, 5A might be sizzling switched at as much as 1kV.

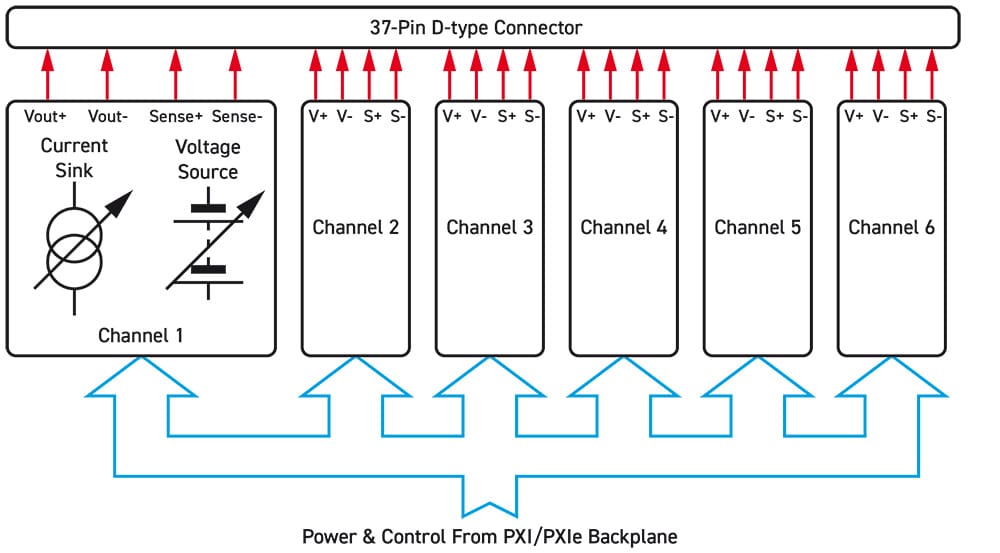

Battery Cell Simulation

Pickering’s PXI/PXIe multi-channel battery simulator module (Determine 1) was created with BMS design and verification in thoughts. The module contains energy provide channels (two, 4 or six per slot) able to supplying as much as 7V and 300mA remoted from each other and from floor. The facility provides on the module can subsequently be used to emulate a stack of battery cells which, as talked about, the BMS have to be confirmed to observe on a person cell foundation. Additionally, every channel can sink as much as 300mA to emulate a battery underneath cost. Every channel offers unbiased energy and sense connections, permitting the simulator to sense a distant load and proper for wiring losses.

RTD & Thermocouple Simulation

RTD (resistance temperature detector) simulators can emulate the habits of optimistic or unfavourable temperature coefficient thermistors, for instance, the PT100 resistance temperature sensor (with a resistance of 100Ω at 0oC), which is often employed in battery packs.

Pickering has PXI simulator modules (with 4, 8, 12, 16, 20 and 24 channels) that may simulate the resistance vary 40 to 900Ω, which equates to a temperature of -150 to 850oC, to a decision of lower than 10mΩ.

Thermocouples are additionally employed in battery packs, notably throughout product growth, due to their excessive accuracy. These too might be simulated in the course of the growth and verification of the BMS forward of its connection to (or integration inside) an precise battery pack.

Pickering has a variety of PXI millivolt thermocouple simulator modules that present 8, 16, 24 or 32 channels of extremely correct low-voltage sources. Every channel might be operated over three voltage ranges to simulate the three commonest thermocouple varieties in use.

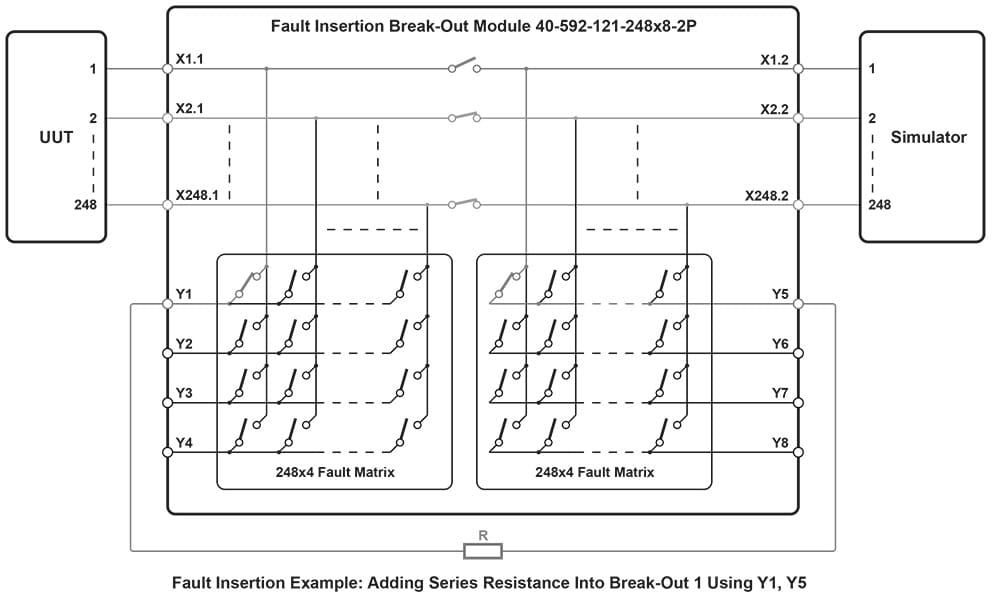

Fault Insertion

Pickering’s vary of PXI fault insertion items (FIUs) – also called fault injection switches – is designed particularly for safety-critical purposes the place the habits of a management system, resembling a BMS, must be absolutely evaluated.

For instance, the 40-592 FIBO (fault insertion break-out) is a large-scale, high-density switching matrix. It’s certainly one of a variety of modules designed for purposes requiring the simulation of varied faults in complicated designs that function a excessive variety of indicators/connections – a battery pack being a first-rate instance. Typical faults that may be simulated are open circuits and quick circuits to both one other sign/part or to floor (see Determine 2).

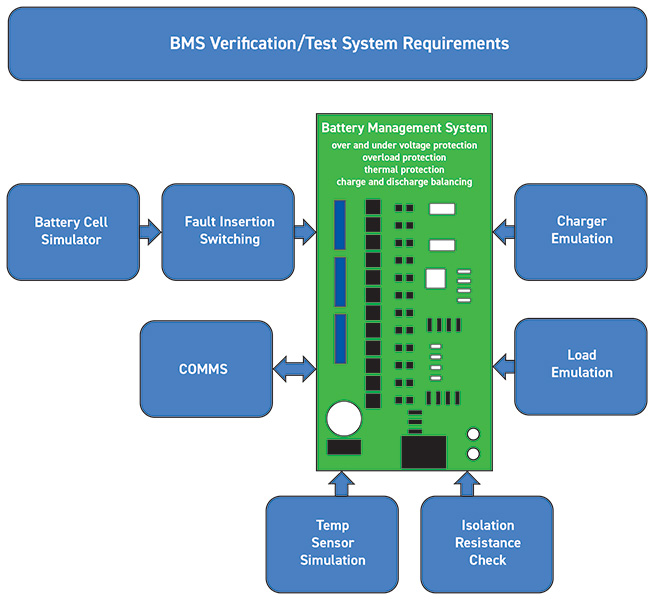

BMS HIL Take a look at System

A complete HIL check system for BMS verification might be created utilizing PXI/PXIe-based modules (see Determine 3 and Video):

- Battery Cell Simulator – simulates every cell’s voltage and present output and has particular person present sinks to emulate cell charging.

- Fault Insertion Switching – simulates short- and open-circuits on every battery cell output, in addition to wiring faults between cells and the BMS. Polarity reversal may also be examined (to confirm that the BMS would acknowledge a producing defect, resembling an inverted cell within the pack).

- Cost Emulation – programmable present supply.

- COMMS – the flexibility to ship instructions to and obtain knowledge from the BMS (in automotive purposes, usually utilizing CAN bus).

- Load Emulation – programmable resistive load to emulate battery stack loading.

- Temperature Sensor Simulation – offers the BMS with inputs from RTDs or thermocouples.

- Isolation Resistance Simulator – verifies the BMS’s electrical isolation monitoring perform.

Collectively, this check system can be utilized in a wide range of permutations to copy all the usual working circumstances the BMS and battery mixture are designed to deal with, and to confirm that the BMS performs all its features, together with cell balancing, voltage and present monitoring, cell balancing, temperature monitoring, reporting faults and taking applicable measures.

Abstract

Simulation is the most secure solution to confirm {that a} BMS’s options carry out as supposed – as a result of it doesn’t contain creating over-voltage or short-circuit circumstances with dwell cells. It is usually straightforward to copy open circuits and temperature extremes.

A complete HIL check surroundings might be created utilizing COTS PXI-based simulators, emulators and fault insertion switches, the place the favored and industry-standard PXI platform offers modularity, flexibility, and scalability.

Importantly, for traceability and certification functions, simulation offers extra significant knowledge that’s straightforward to seize and file.

[ad_2]